PreonLab

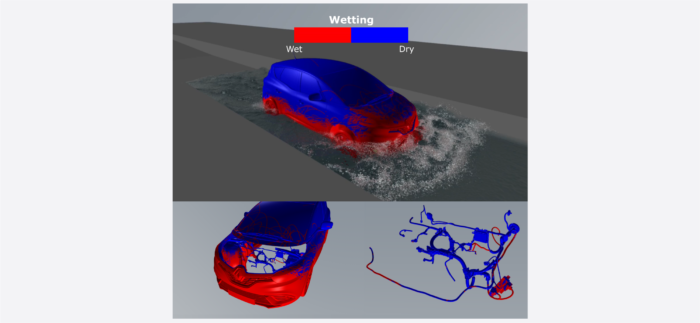

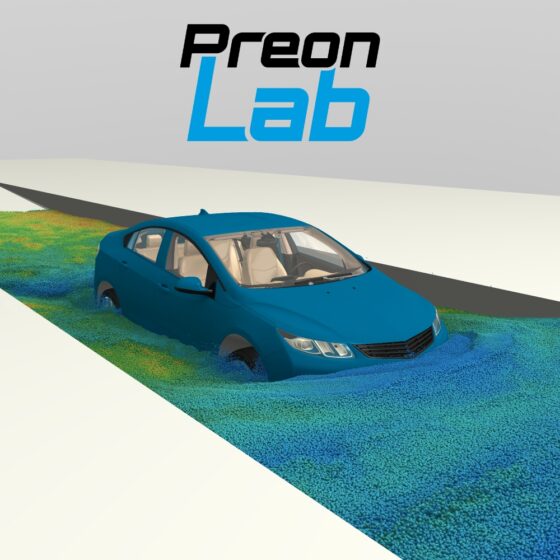

Vehicle Water Wading: Post-processing

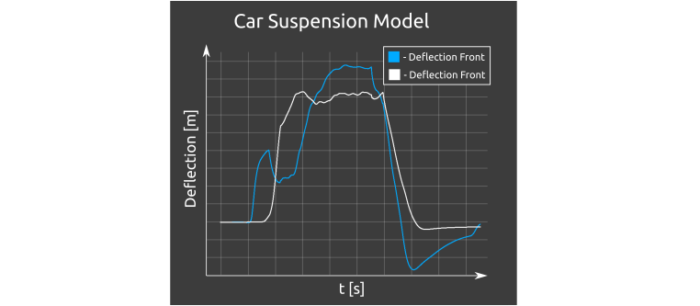

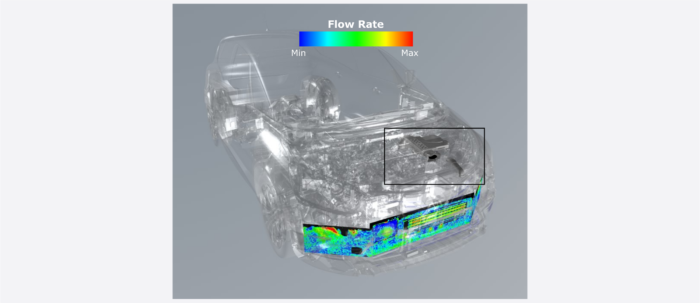

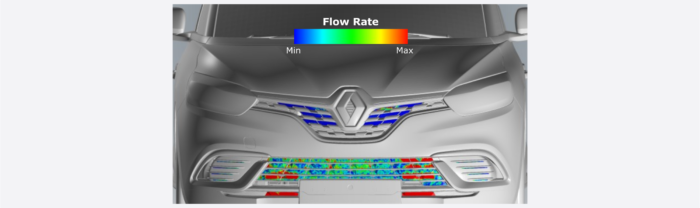

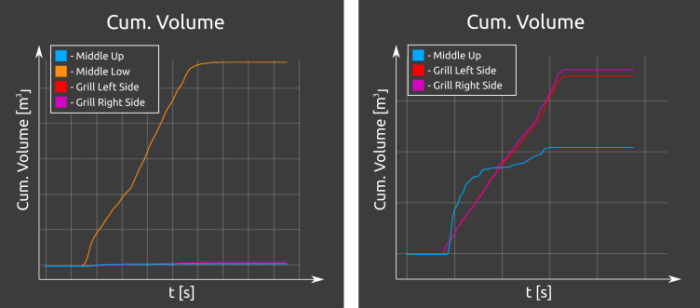

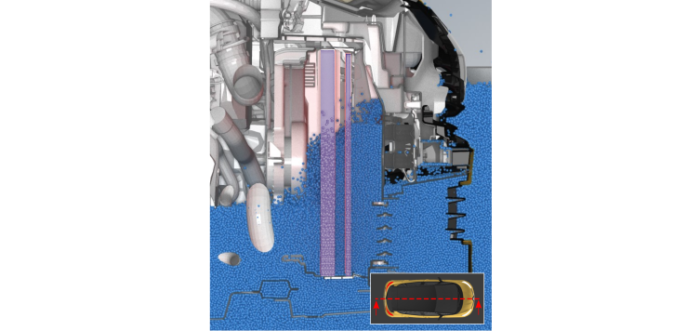

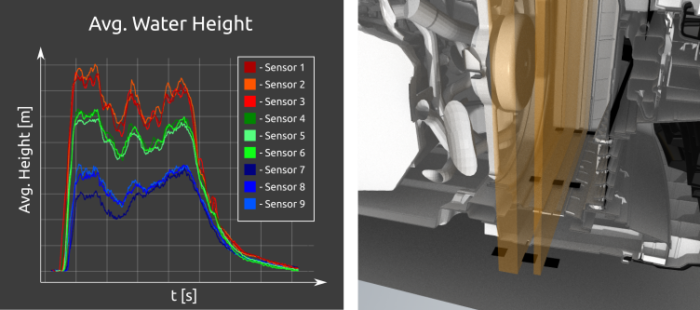

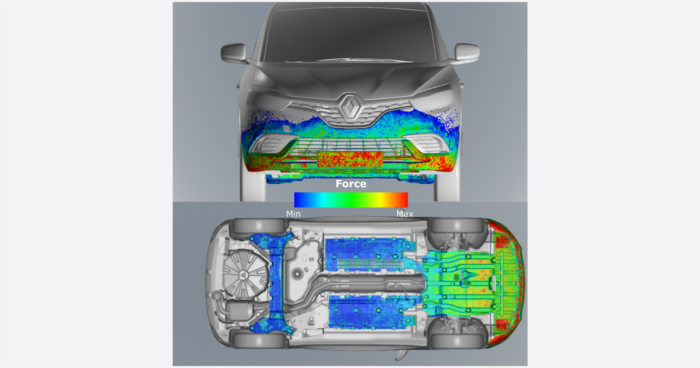

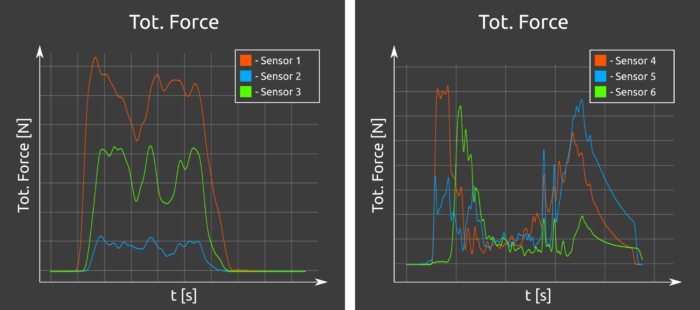

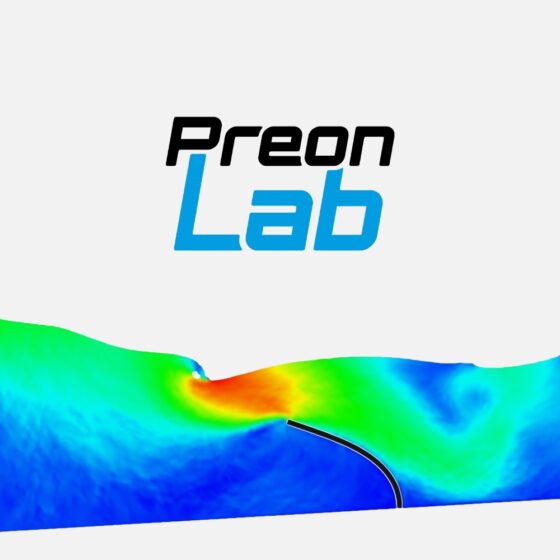

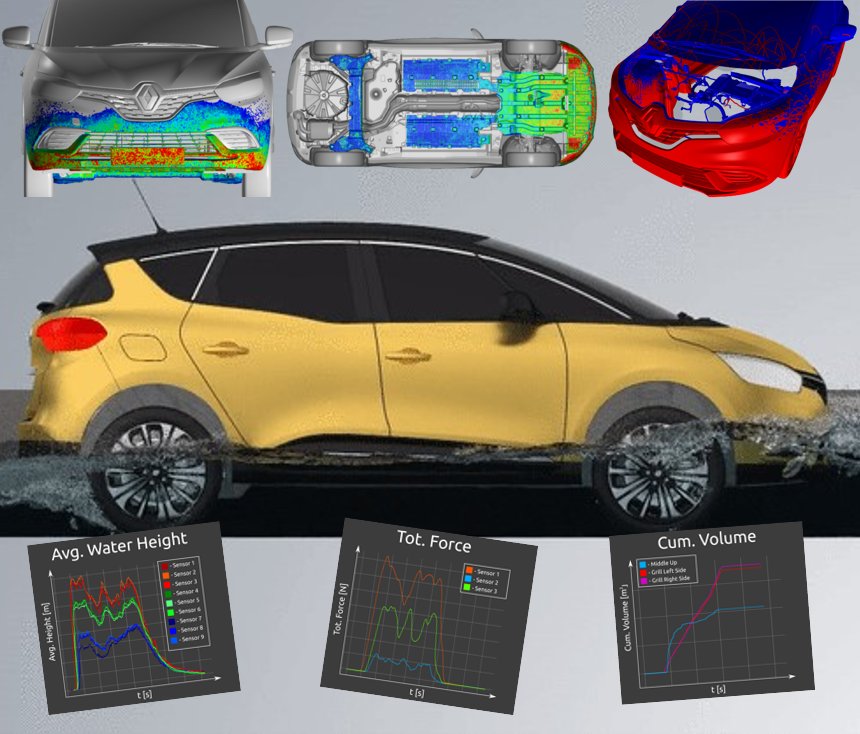

Being one of the flagship applications of PreonLab has made it important to offer various post-processing possibilities to address the needs of the users when it comes to water wading simulations. You can gain loads of insight by performing a full wetting analysis, measuring the flooding height, predicting under-body forces and understanding the flow paths for the regions of interest as well as measuring flow rates of water entering the engine compartment or any critical part of the vehicle.