Schaeffler Customer Success Story

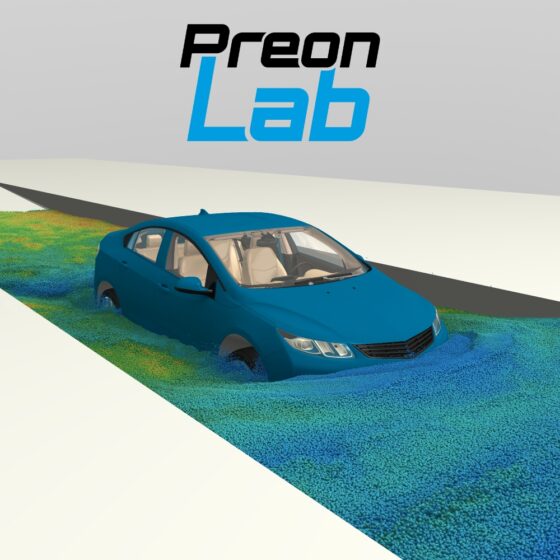

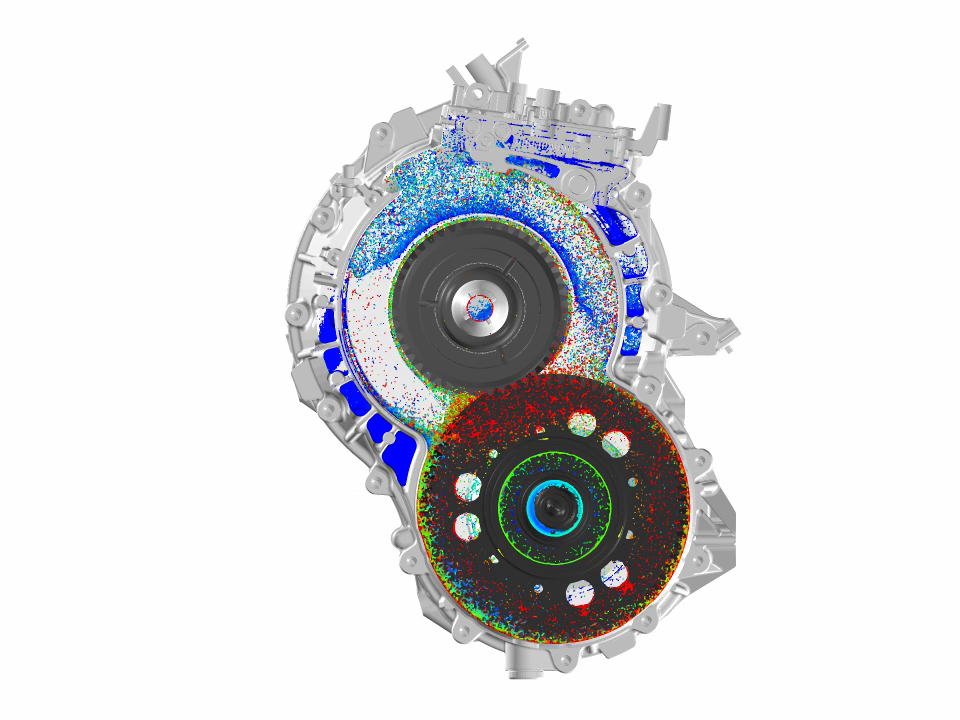

Shorter Development Cycles Through Virtual Prototyping

Thanks to the electrification of the powertrain, innovation in the automotive industry is happening faster than ever. Short time to market for electric vehicles (EVs) and hybrid vehicles (HEVs) is one key to be successful for OEMs and tier 1 suppliers.