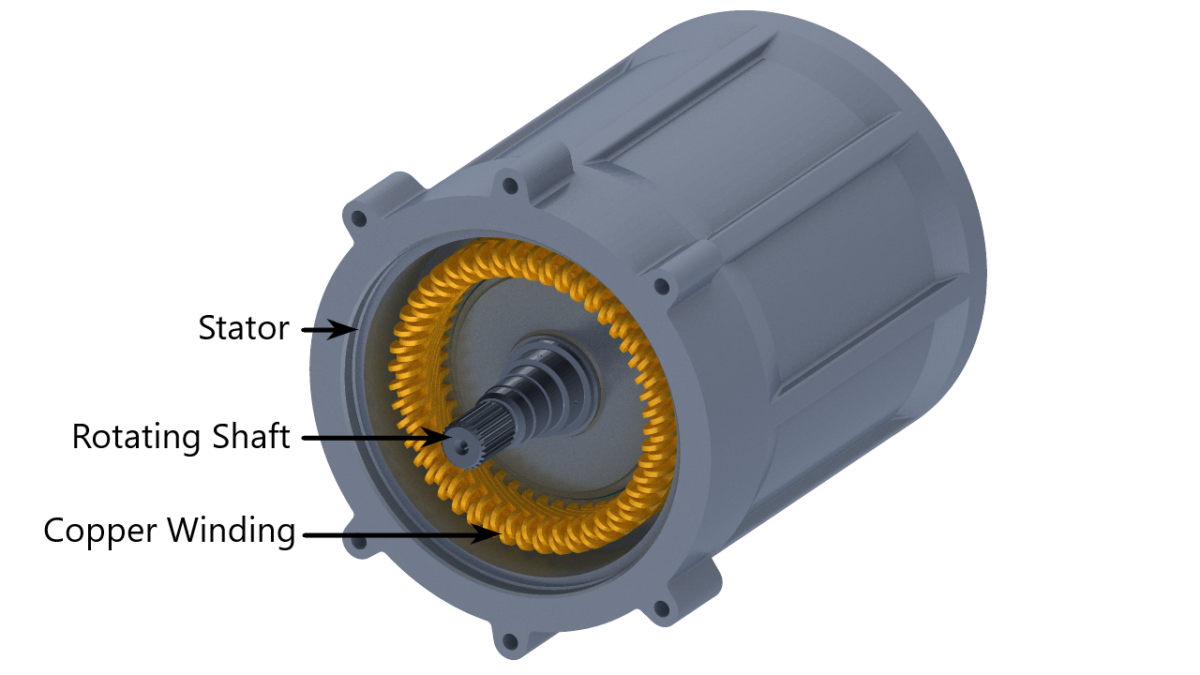

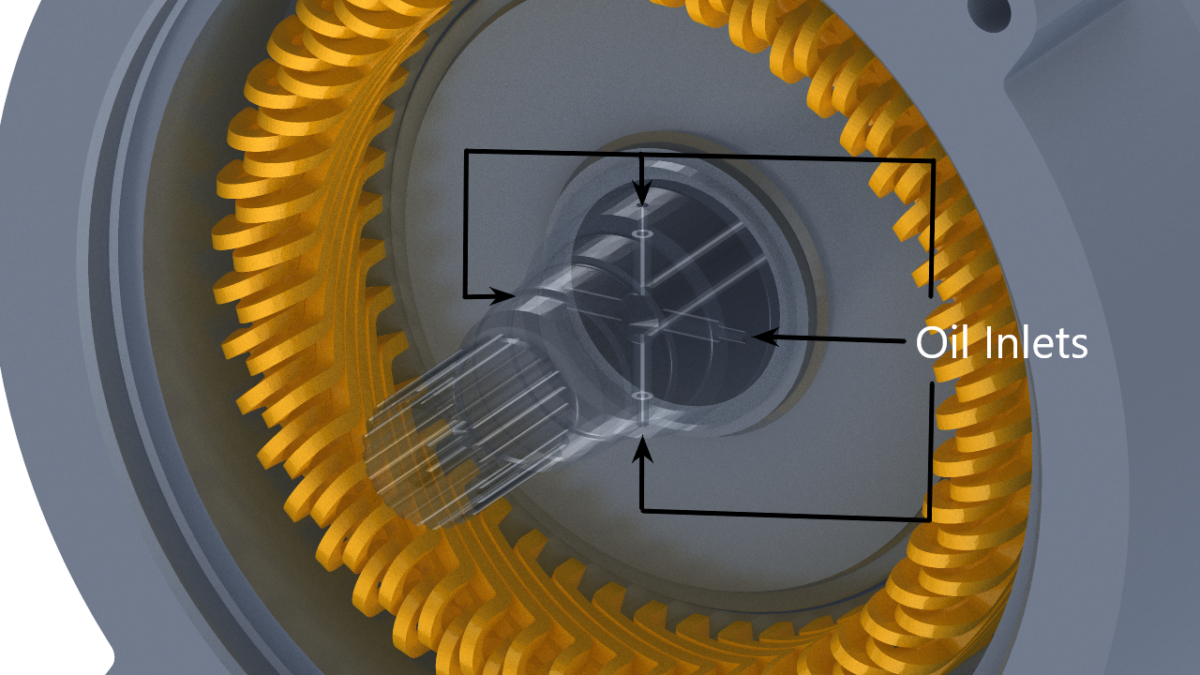

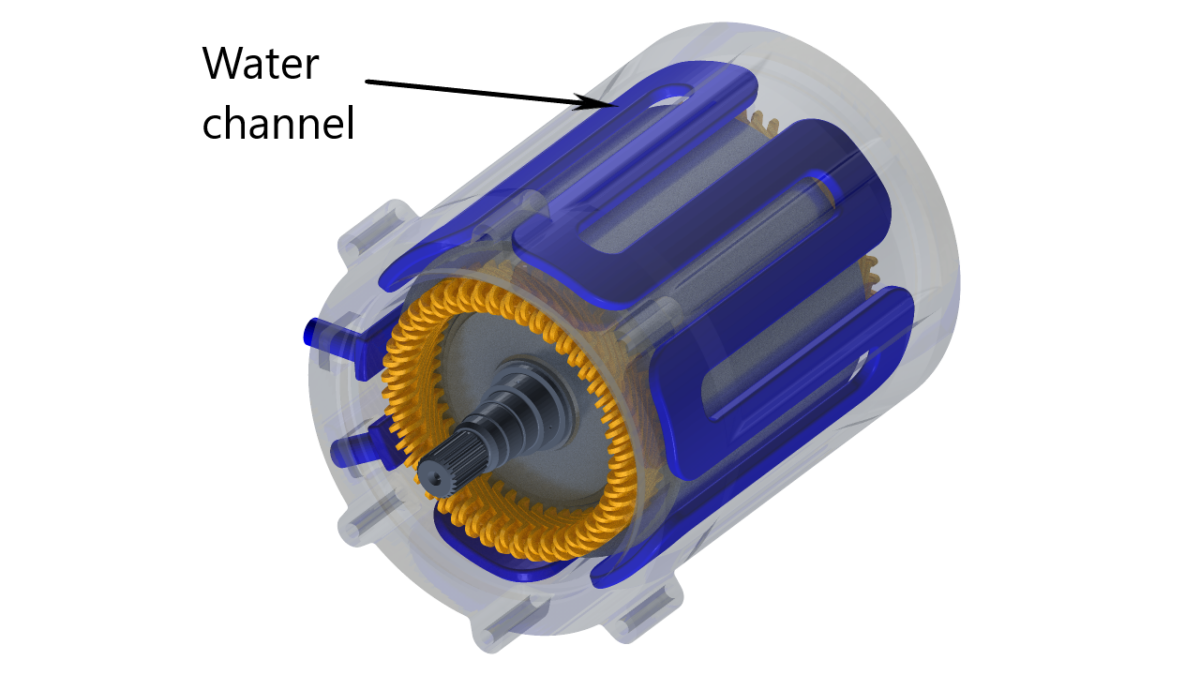

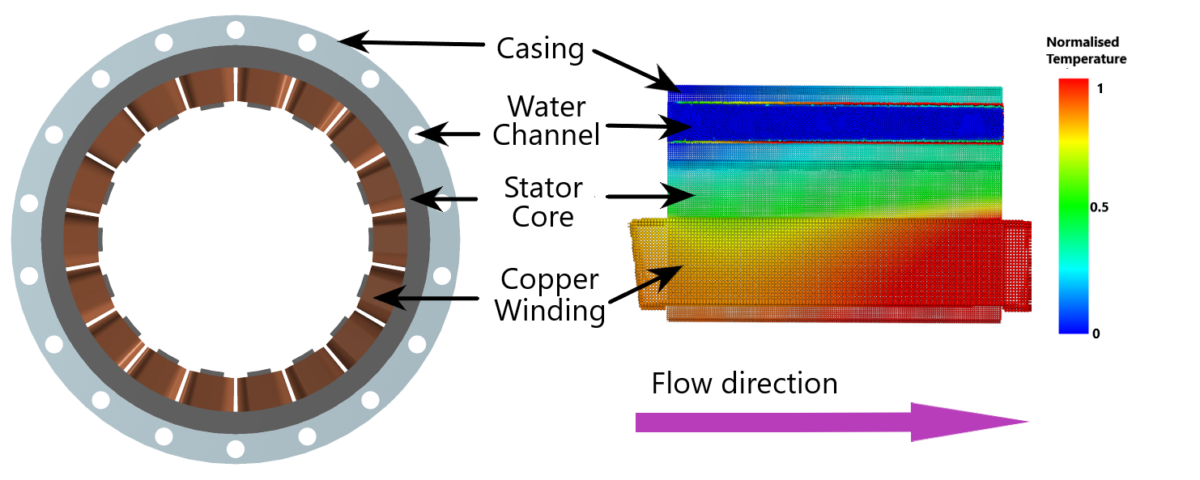

Electric motor or e-motor cooling is a vital aspect of the thermal management system for vehicles. Efficient cooling leads to significant boosts in performance and contributes towards the use of smaller motors for a given application or increasing the range of batteries. As a result, it is crucial to meet the space, weight, and cost targets of the project.

Making use of CFD simulations can deliver great insights into the e-motor cooling process to optimize the design stage. However, running comprehensive simulations for e-motor cooling can be rather costly in terms of computational power.

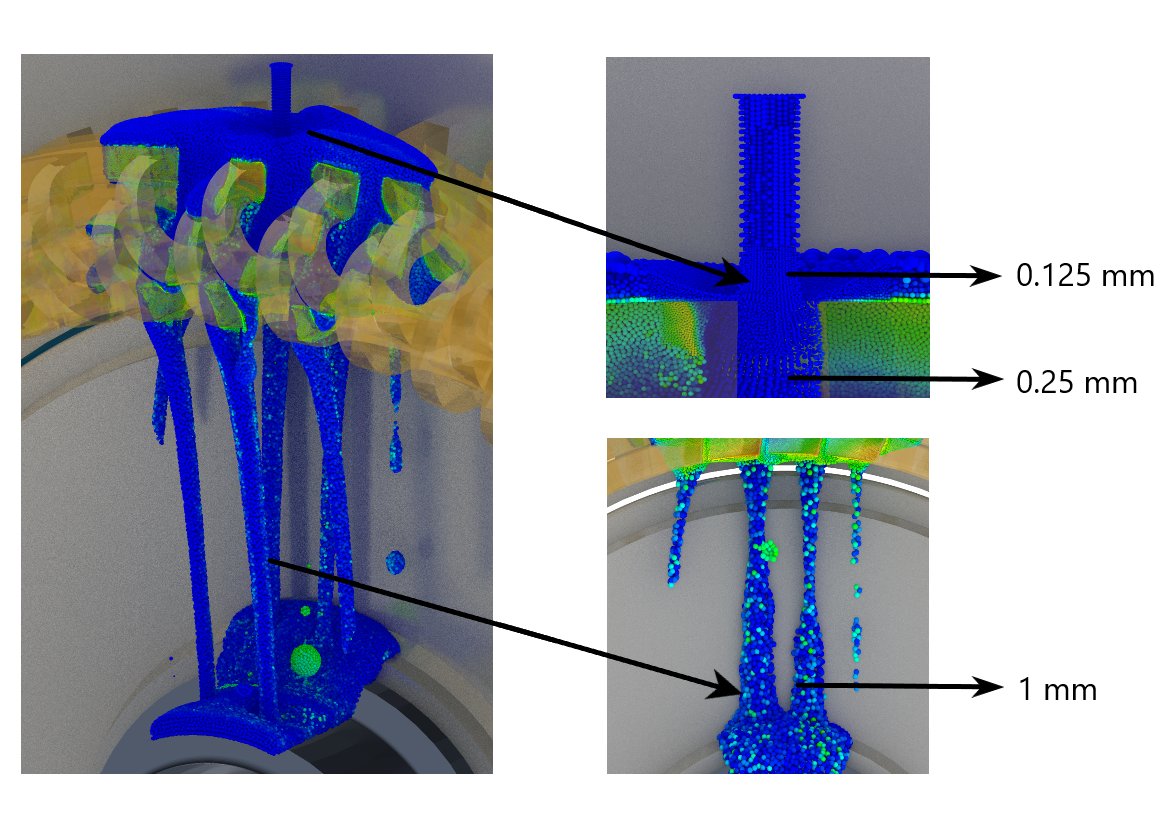

This is a great opportunity to apply the new Continuous Particle Size (CPS) feature which allows fine particles for regions where we have a large amount of heat transfer, and efficiently increases the particle size of the fluid in the regions of lower interest. Details about Continuous Particle Size (CPS) can be found in the article: “Continuous Particle Size (CPS) and Adaptive Refinement“. As a result, the number of particles required in the simulation is minimized and the computational effort can be reduced.

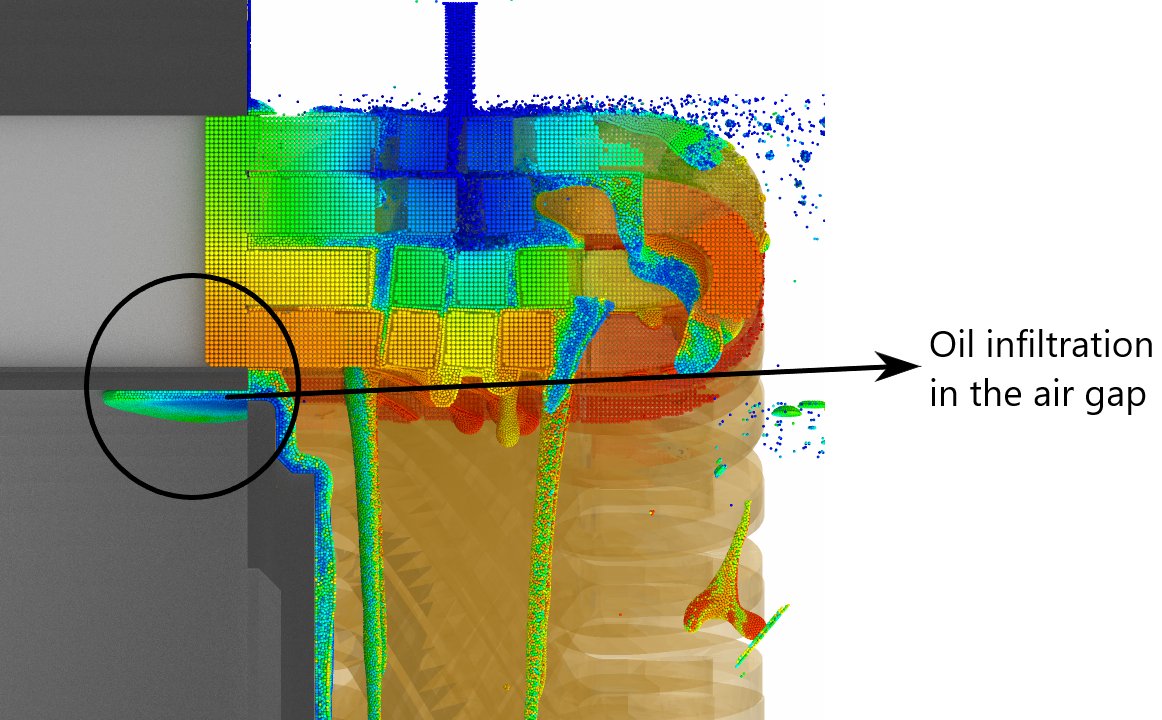

Apart from this, a volumetric heat source is necessary to best simulate the heat generated within the components of the e-motor. Up until now only surface thermal boundary conditions were available in PreonLab.

Now with version 5.2 and PreonLab’s new feature called heat field, a user-defined heat source can be generated within a volume. The heat source can be applied to the domain and controlled spatially via an embedded geometry or even a point cloud resource.

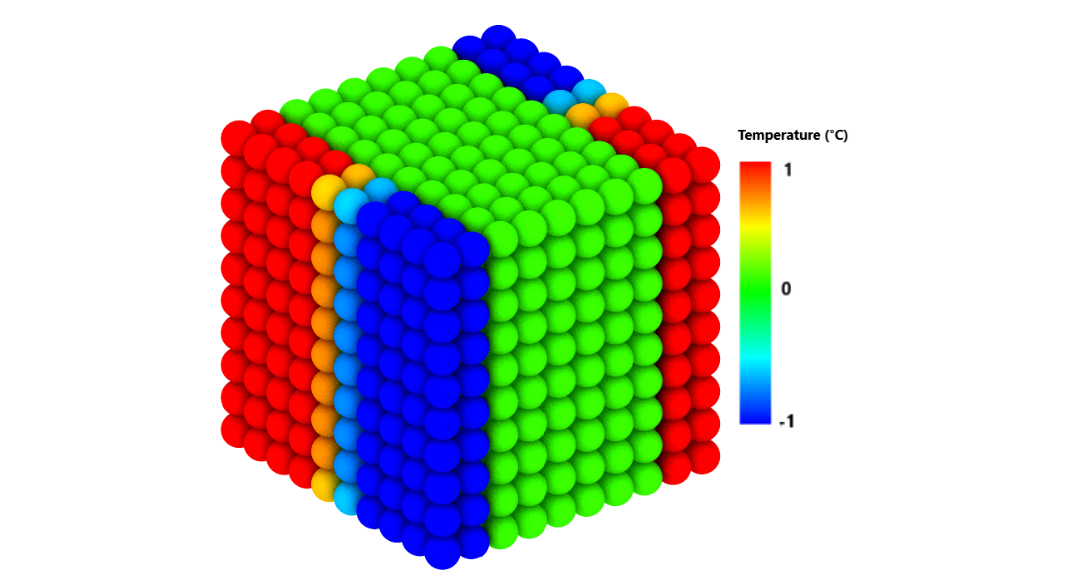

A point cloud resource object in PreonLab is a cloud of sampling points that can be assigned with different user-defined values such as heat source strengths.

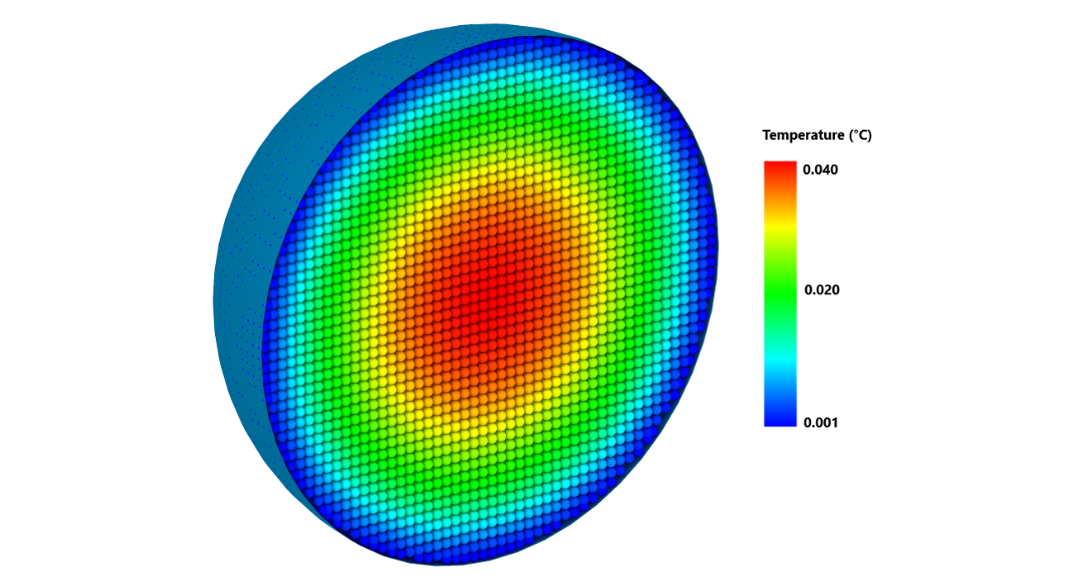

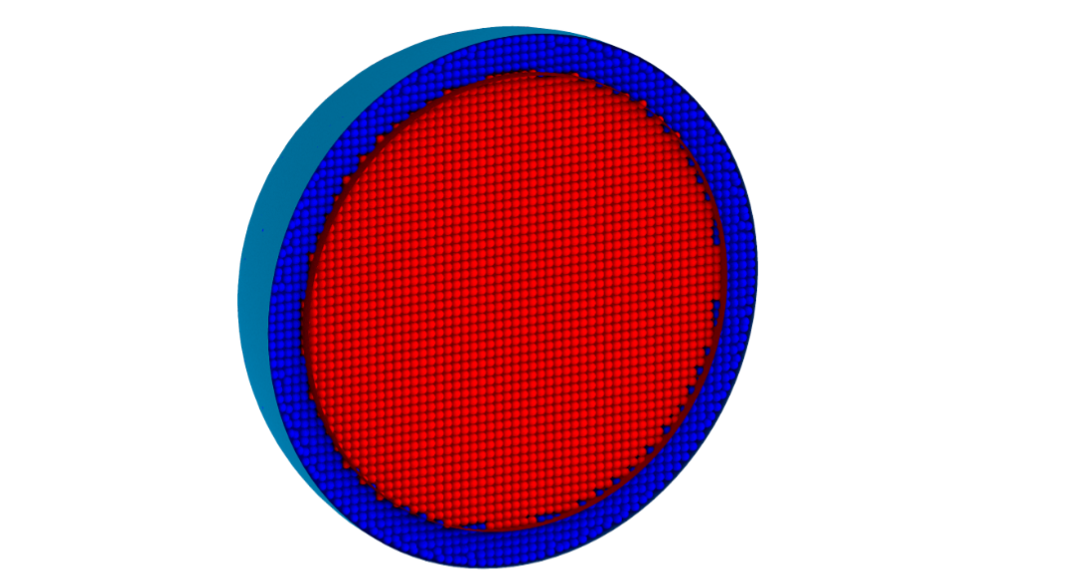

Figure 1a depicts the temperature distribution in a sphere resulting from a uniform heat field, Figure 1b showcases the use of an embedded spherical geometry to control where the heat field is applied (red particles), and Figure 1c shows the concept of applying the heat field via a point cloud resource object.