Ensuring thorough lubrication in a gearbox is a complex problem that is hard to cover on a test bed. While glass boxes enable the visibility of oil distribution, the information that can be extracted from the gearbox test bed for higher rotational velocities is minimal, even with the use of high-speed cameras. Additionally, repeating tests for different operating conditions or simply due to faulty measurements can rack up the expenses rapidly.

Simulation methods can provide effective solutions to these challenges by enabling design adjustments, multiple iterations for various operating points, and virtual extraction of all relevant data for analysis and post-processing. You can simulate multiple runs in parallel, rather than performing just one run at a time on one test-rig. Nevertheless, the simulation of a gearbox is a demanding challenge for most numerical CFD methods, due to the complexity of geometry and kinematics.

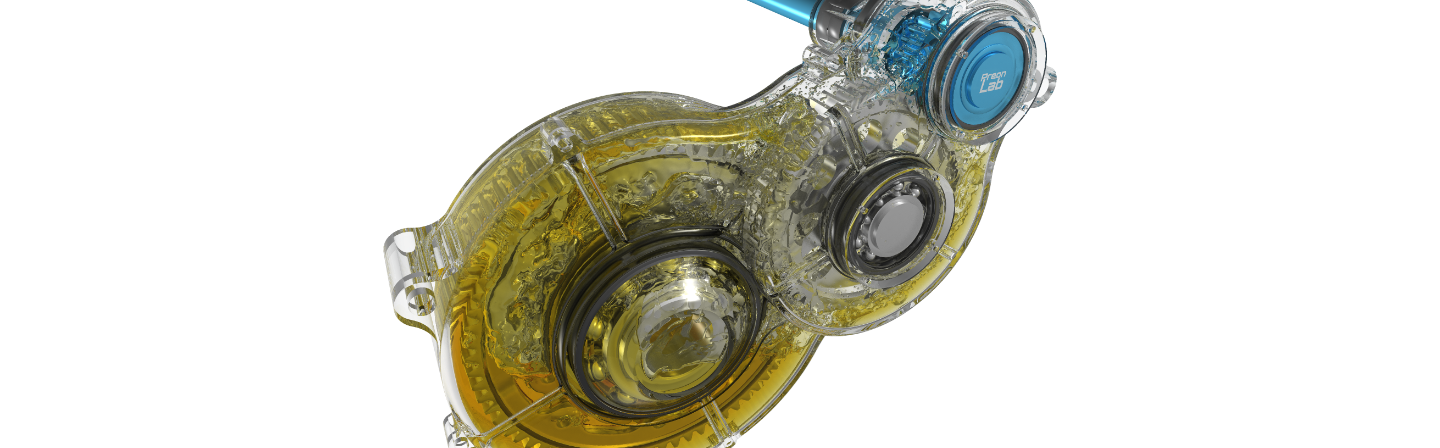

PreonLab is based on the implicit Smoothed Particle Hydrodynamics (SPH) method, which is well-suited for the rapid simulation of complex scenarios involving free surface flows, as is the case with gearbox applications. It enables the analysis of lubrication distribution and power-loss calculation with unmatched efficiency. PreonLab allows importing geometries within seconds and does not require mesh-generation due to its purely Lagrangian simulation approach. Even for complex setups, e.g. planetary gearboxes, kinematics can be defined in a few minutes. As a result, the time you spend setting up the simulation is reduced to a minimum. Owing to PreonLab’s inherently fast and efficient solver code, and the Python-based API, PreonPy, multiple design variants can be simulated very quickly and efficiently. Additionally, PreonLab’s advanced adaptive refinement and coarsening algorithm (Continuous Particle Size) and GPU support make it possible to perform simulations at unparalleled speed. Easy-to-use post-processing and visualization tools enable rapid analysis iterations to finalize optimal gearbox designs within no time. For example, derived quantities like total power loss can be calculated within PreonLab with the help of calculation objects removing the need to rely on external tools. Keep reading to discover the PreonLab workflow for simulating gearbox applications, important aspects of the application that can be simulated, the virtual insights you can gain from the simulation, and what our customers say about the use of PreonLab to optimize their gearbox and transmission designs.

Video 1: Gearbox Simulation performed by Merkle & Partner.

Video 2: Planetary Gear Simulation performed by Merkle & Partner.

Whether it is automotive transmission, industrial gear systems, aerospace systems or gearboxes in wind turbines, simulating with PreonLab boosts the pace of gearbox development across several industries. Different aspects of gearboxes can be simulated and analyzed with PreonLab:

Simulate Dynamic Conditions

PreonLab can simulate transient states, such as ramp-up, shutdown, or sudden load changes, to analyze their effects on lubrication and gear performance. The kinematics can be defined very easily using the keyframe editor. With the help of keyframes, you can specify how desired properties change over time. For instance, keyframing the orientation or rotational velocity helps to conveniently define the rotation of the gears over time.

Additionally, PreonLab allows the usage of real bulk modulus values, which enhances the quality and accuracy of the simulation and improves the workflow by eliminating the need to fine-tune setup parameters.

Video 3: Defining the Ramp-Up and Shutdown Kinematics of the Input Shaft and Gear in the Keyframe Editor in PreonLab.

Rigid Body Dynamics

Video 4: Gearbox Simulation using Rigid Body Dynamics in PreonLab.

Multiphase Simulation

Single phase simulations are an efficient method to deliver accurate results for many cases involving more than one fluid, such as gearboxes with low rotational speeds, where the behavior of the oil is not significantly affected by the presence of air. It is also generally possible to model the second, less-significant fluid phase as a boundary condition (for example drag force for air) if required.

However, this situation changes when the air phase becomes more influential and introduces additional effects which are not captured in basic single-phase simulations. For cases like gearbox simulations with high rotational speeds, multiphase simulations are the most accurate method to achieve realistic results.

Video 5: Multiphase Simulation of the Gearbox Setup at the Forschungsstelle für Zahnräder und Getriebesysteme (FZG) Testbench.

It is possible to obtain detailed visualization of how lubricants are distributed under varying conditions in PreonLab. The software helps assess how well the lubricant is distributed over all components, which becomes increasingly important in high-speed or high-load scenarios. Additionally, you can detect unwanted ingress in areas which should be kept free of oil. The simulations also provide information about the forces and resulting pressures and torques acting on the gears. This can be useful in determining the system’s overall power loss. Furthermore, it is possible to simulate heat generation within solid gears with the solid volume solver as well as the Conjugate Heat Transfer between the gears and the cooler oil with the help of the thermal solver.

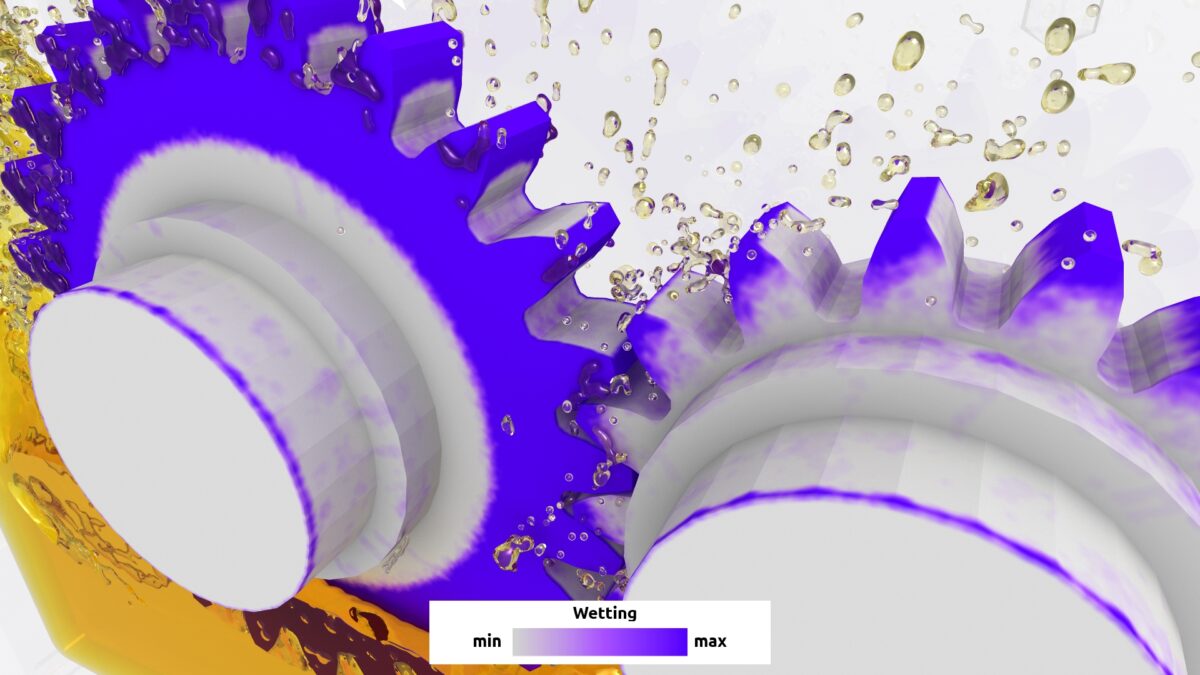

Wetting Analysis

The lubrication distribution can be analyzed using the wetting sensor, which measures and visualizes both the current and total amount of wetting on any connected solid object. Additionally, the sensor tracks and displays the duration of contact between the object and the lubricant. This enables you to identify which parts of the gears interact with the oil and detect any regions that may not receive sufficient lubrication.

Figure 1: Visualization of the Wetting Distribution for Two Gears using the Wetting Sensor.

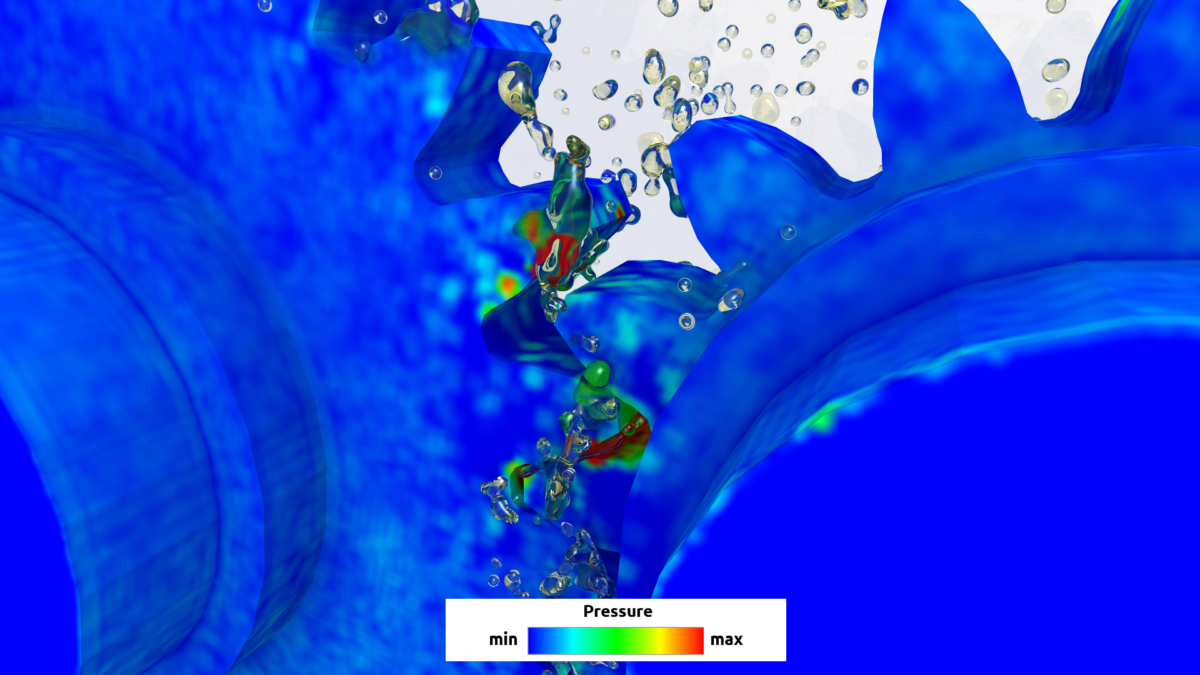

Force and Pressure Analysis

The force sensor measures the forces exerted by the lubricant on the gears and other components of the simulated gearbox, along with the resulting pressure and shear stress on solid objects. The recorded forces and torque measurements are categorized into pressure, friction, adhesion, and total forces. Additionally, the net sum of all forces acting on each solid object is calculated for every measured force. These statistics can be used for further analysis—for instance, the total torque per gear can help determine the system’s overall power loss. The entire analysis can be efficiently conducted within PreonLab using Calculation Objects.

Figure 2: Visualization of the Pressure Distribution for Two Gears using the Force Sensor.

Thermal Analysis using the Solid Volume Solver

By default, solid objects in PreonLab are sampled only on their surfaces. However, by adding a Solid Volume Solver and a Solid Volume Source, sampling can be extended to the entire volume of the solid. This enables the simulation of heat dissipation within the solid. You can define thermal properties such as specific heat capacity and thermal conductivity for the gear material. Heat generation within the gears can be simulated using the heat field, which is a volumetric heat source in PreonLab, and the resulting heat exchange between the gears and the cooling lubricant can be analyzed using the thermal solver.

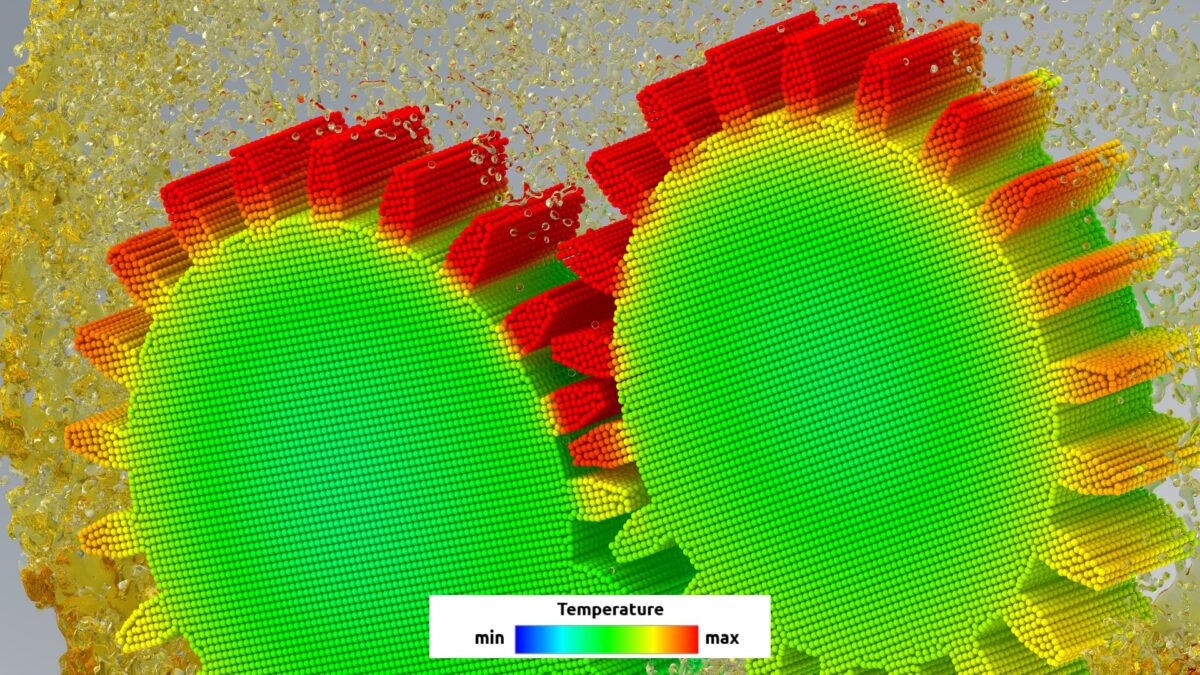

Figure 3: Visualization of the Temperature Distribution within Two Gears using the Solid Volume Solver.

Video 6: Gearbox Lubrication Simulation for E-axle Systems performed by Schaeffler Technologies.

PreonLab is equipped with its own Python-based API called PreonPy. The Preon solver and most of the features found in PreonLab are accessible via PreonPy, which lets you automate loading and saving scenes, modifying properties, starting simulations and fetching statistics via a Python script. This lets you automate the creation and simulation of multiple simulation variants, which is especially desirable when performing simulations for different operating conditions or design variants. The following videos show the different lubrication distribution which arises due to differing operation conditions (rpm, oil fill volume).

Video 7: Planetary Gearbox Simulations performed at different Operating Conditions, Setup instantly using PreonPy.

For more information on how PreonLab can help tackle your simulation challenges, get in touch with us here.